Guide to expanded metal, types, materials and production process

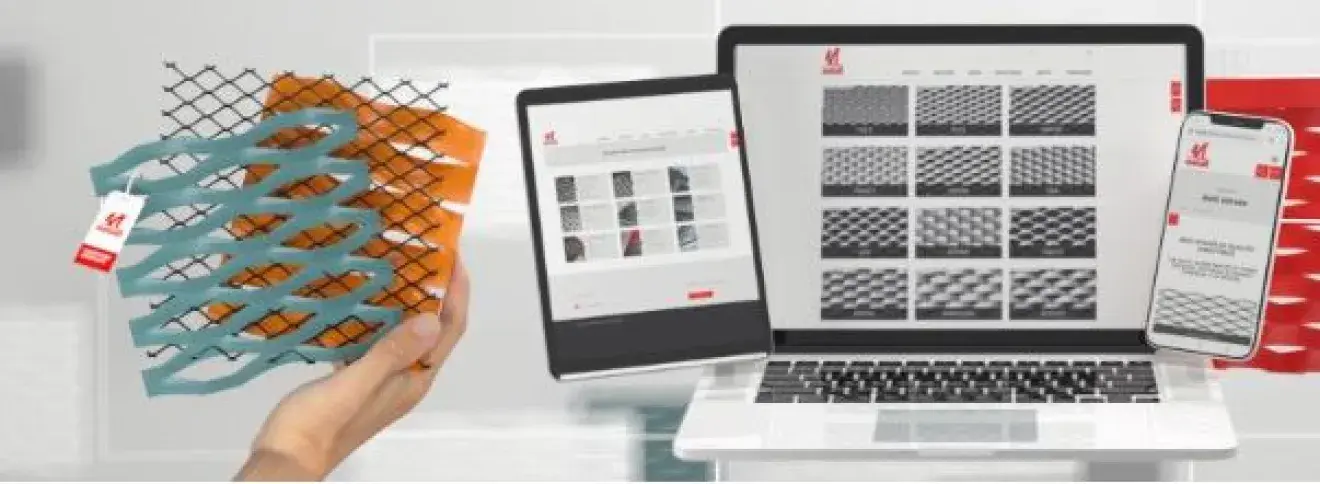

Expanded metal (also known as expanded metal mesh) is an open metal material that can be used for cladding in construction and architecture. It can be used in a variety of industrial sectors for robust, non-slip walkways and plant protection. Thanks to the wide range of available options and the possibility customisation, it can meet the technical and aesthetic requirements of any project. Browse the available range of Fils expanded metal sheets now.

What expanded metal is and how it is produced?

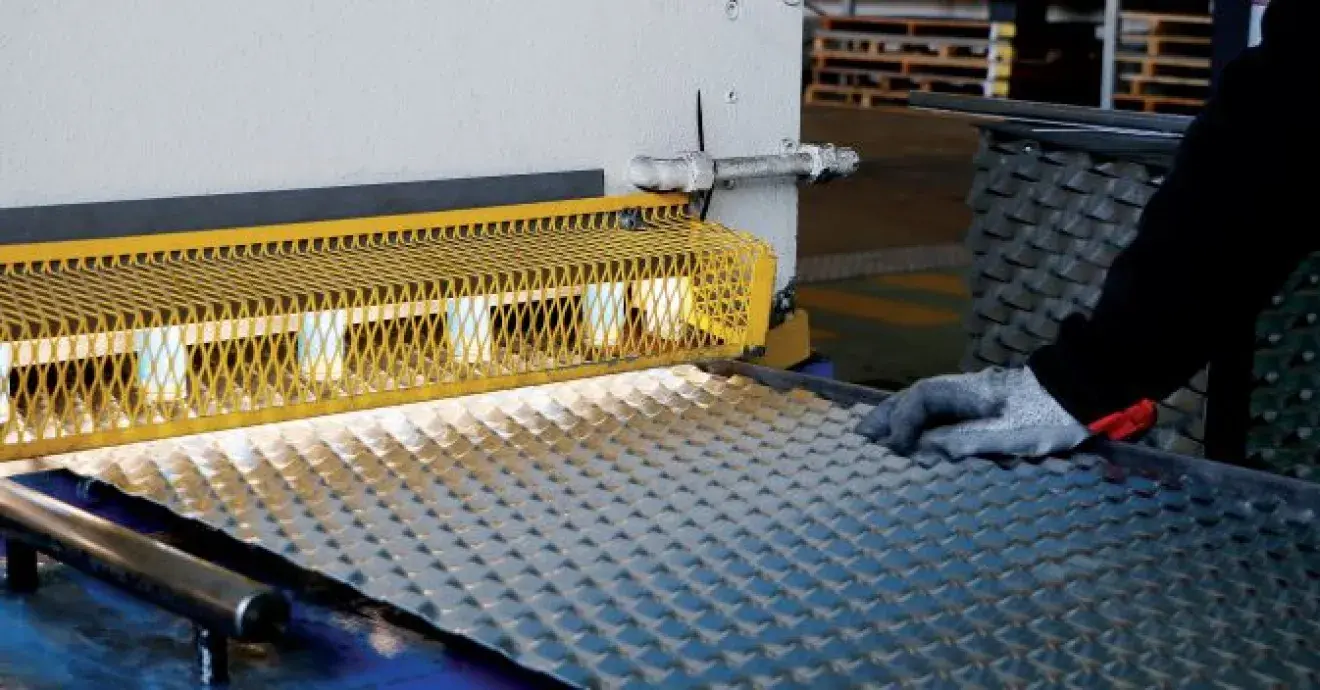

Expanded metal is a material, usually metal, which has solid parts and hollow parts. It is obtained by a combined process of engraving and stamping using a tool called a ‘knife'.

- The width and shape of the metal mesh varies dependent on the shape of the ‘knife’ used.

- There is no waste - all metal is used and maintained

- The structure of the metal is strong, robust and resistant. It is a logical solution for protecting people and isolating dangers.

Sheets, rolls and coils. Standard and customised formats available.

Expanded metal can be produced in coils, rolls or sheets.

- Sheets: the material is rigid and is supplied in commercial sizes of: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm.

- Rolls: the material is semi-rigid and is rolled up to a predetermined length. For example, rolls of 6 metres or 10 metres can be made.

- Coils: thin, not excessively stiff material can be wound into coils. The quantity is supplied in the desired length.

Fils offers a dedicated cut-to-size service and can prepare sheets, rolls or coils in the desired, custom dimensions. Consult our experts for all information on made-to-measure formats.

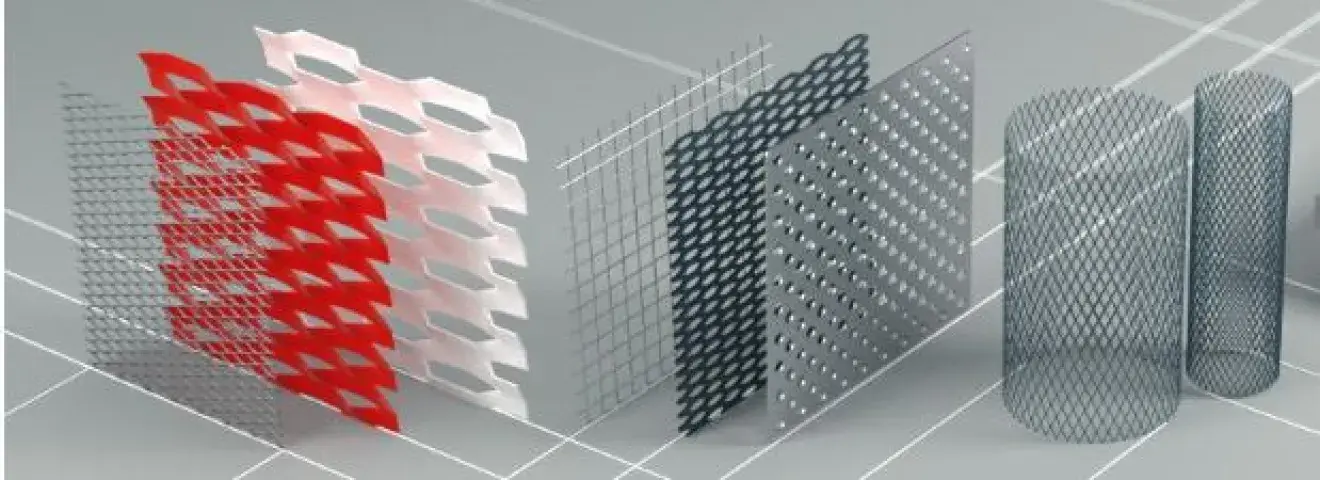

The geometry of the meshes

Fils offers 3 different geometries for its metal meshes:

For each geometry, countless mesh size 'variants' are also available, in order to meet even the most specific requirements of an application. Reach out to our expect team and we can provide a free samples for evaluation.

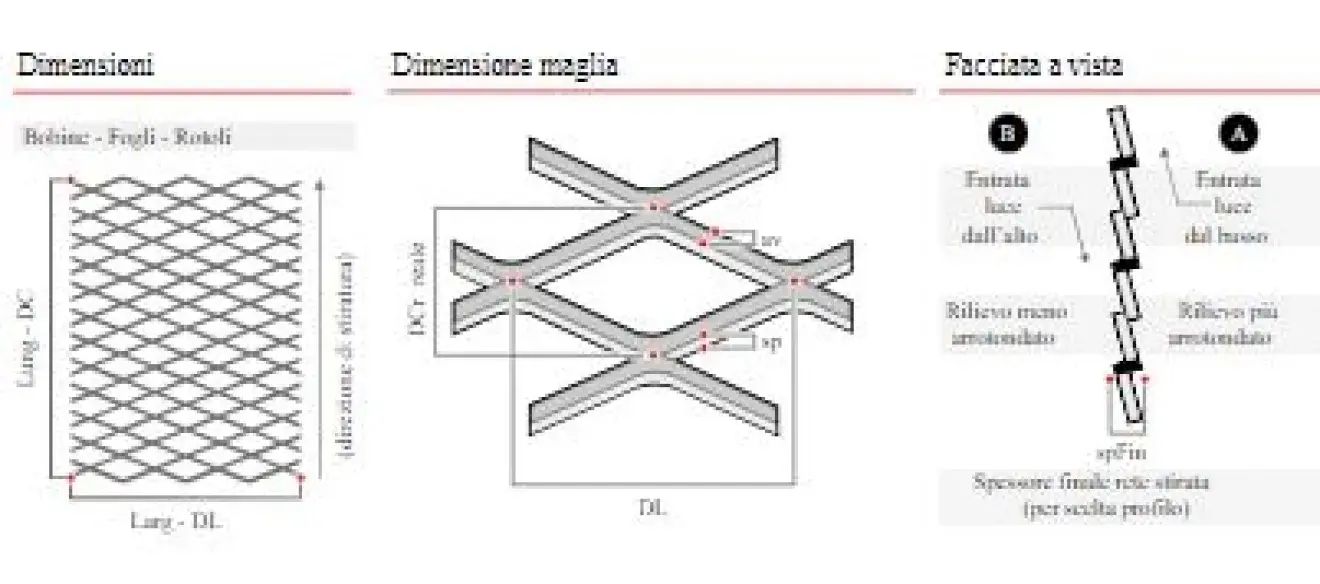

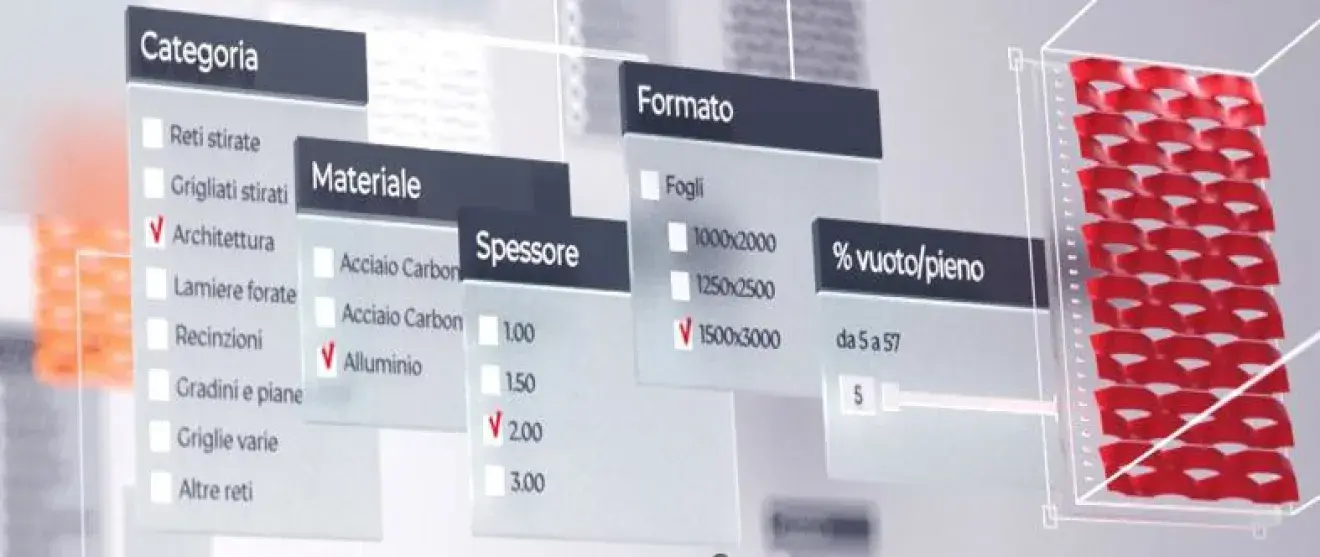

Key for identifying expanded metal

There are four parameters which are needed to fully define an expanded metal model. (To these we must then add the material chosen):

- Long Way pitch (LW)

- Short Way pitch(SWn)

- Strand widht (w)

- Thickness (t)

Below is an example key relating to the diamond geometry mesh. Each product then has a more specific and complete key associated with it. Or: Scroll down to see the gallery to see the specific key.

Stretchable materials and expanded metal processing

Expanded metal sheets (also called expanded metal mesh) can be made of Carbon Steel, Sendzimir Carbon Steel and also Aluminium, Copper and many other materials. Durability is guaranteed by the protective finishes available in a range of colours.

Expanded metal can be:

- Cut to size

- Folded and pleated

- Curved and wavy

- Edged with C-, L-, U-shaped profiles

Do not hesitate to contact us for more information and finding the right product for your application.

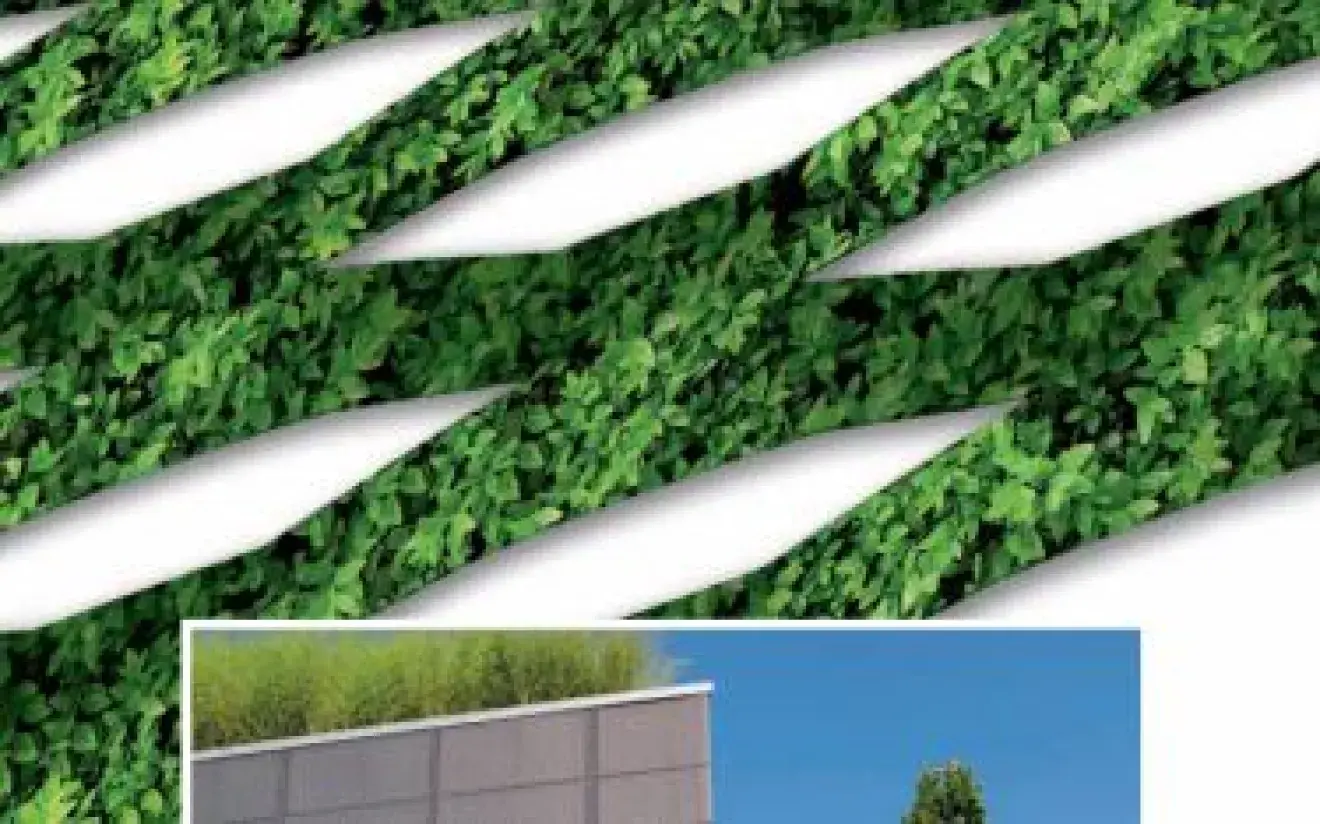

The areas of use for expanded metal

Thanks to the wide range of models available, with different geometries and thicknesses ranging from 1.5 mm to 5 mm, expanded metal can be used in a variety of applications such as aesthetic cladding, masking and strong protection. Fils offers semi-finished and finished products such as steps, landings and walkways for the construction industry. Modular expanded metal elements are used to make facades, sunshades, fences, parapets and many other applications in architecture. As far as industry is concerned, plant protection, non-slip walkways, masking of electrical equipment, partition walls are realised.

Sustainability for Fils: Environmental impact is essential

The environment is a priority, and Fils is committed to sustainability on several fronts.

- The use of Clean Energy: more than 90% of the energy required for the production of the expanded metal sheet comes from the company's solar power systems.

- The processes are non-polluting: 'ironing' is a cold stamping process that does not require the use of pollutants.

- Production is 'zero waste': the way expanded metal is produced is without any material waste and thus optimises the use of raw materials.

- It is recyclable: at the end of their long lifecycle, the expanded metal sheets are taken to the separate waste collection and can be 100% recycled.

See resources

FAQ

Expanded metal can be produced using various materials that can be 'stretched' thanks to their mechanical characteristics.

The most commonly used materials in the construction industry are undoubtedly carbon steel and Sendzimir carbon steel. Aluminium is used for cladding applications in architecture. Expanded metal sheets can also be made from various types of stainless steel (e.g. AISI 304, AISI 316 and others) for applications that require specific resistance properties in high temperature environments or corrosive atmospheres.

Expanded metal and perforated metal are both 'open' materials. Expanded metal is produced using a 'slitting and stretching' process without wasting any of the raw material; perforated sheet metal, on the other hand, is obtained by a 'punching' process resulting in metal scrap. Another difference between these materials is the thickness: expanded metal has a three-dimensional shape that also adds to its strength. Perforated sheet metal is flat, with a constant thickness. Expanded metal can be used instead of perforated metal for many applications.